Phone Number :

11 18, 2024

In construction, interior design, and various industrial applications, PVC co-extruded plastic trim has become an essential material for edge protection. Its cost-effectiveness, durability, and versatility make it an ideal choice for both residential and commercial projects. This article explores the features, benefits, and common applications of PVC co-extruded plastic trim.

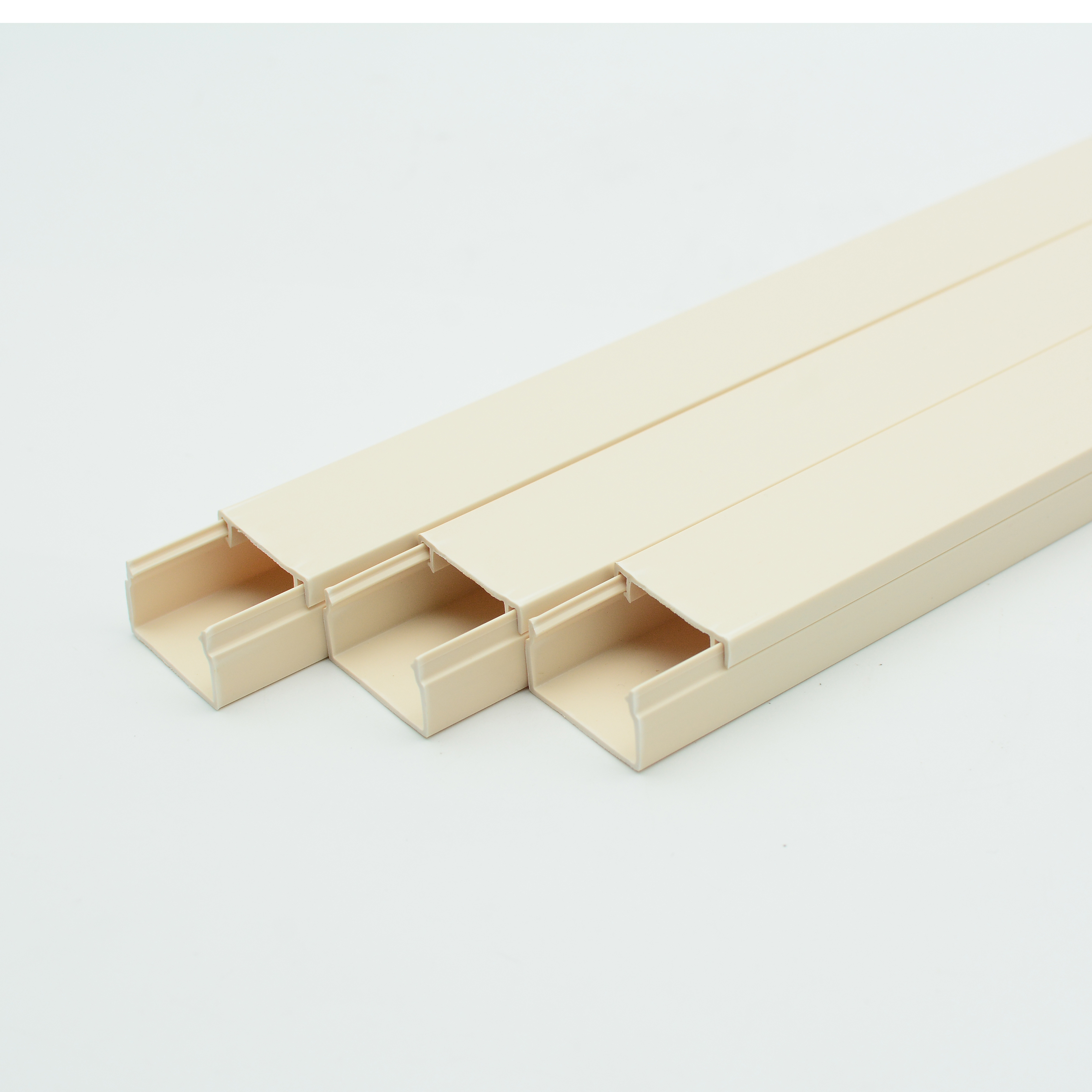

What is PVC Co-Extruded Plastic Trim?

PVC co-extruded plastic trim is a type of plastic molding made by combining two or more PVC materials through a co-extrusion process. This process allows the trim to have a durable core and a flexible or aesthetically enhanced outer layer, delivering a balance of strength and visual appeal.

Benefits of PVC Co-Extruded Plastic Trim

1.Cost-Effectiveness

PVC co-extruded plastic trim is an economical choice compared to other materials like aluminum or wood. Its affordability does not compromise its performance, making it a preferred option for projects with budget constraints.

2.Durability

Thanks to its co-extruded design, the trim offers exceptional durability. It resists cracking, warping, and damage from environmental factors like moisture and UV exposure.

3.Low Maintenance

PVC co-extruded plastic trim requires minimal upkeep. Unlike wood, it does not need painting, staining, or sealing. Cleaning it with a damp cloth keeps it looking new for years.

4.Aesthetic Flexibility

The co-extrusion process allows the addition of custom colors, textures, or finishes. This makes it suitable for projects where appearance is as important as functionality.

5.Eco-Friendly

PVC co-extruded plastic trim is often made using recyclable materials, reducing waste and contributing to sustainability in construction practices.

Applications of PVC Co-Extruded Plastic Trim

1.Edge Protection

PVC co-extruded plastic trim is commonly used to protect edges in furniture, countertops, and paneling. Its robust construction prevents chipping and wear over time.

2.Construction and Architecture

In buildings, it is often used as a protective or decorative element around windows, doors, and flooring. Its weather-resistant properties make it ideal for both indoor and outdoor use.

3.Automotive and Industrial Applications

The material is also popular in automotive interiors and industrial machinery to provide a finished look and protect sharp edges from damage or injury.

4.Retail and Display Solutions

Retail displays and signage frequently incorporate PVC co-extruded plastic trim to enhance durability and maintain a polished appearance.

Why Choose PVC Co-Extruded Plastic Trim for Edge Protection?

When it comes to edge protection, PVC co-extruded plastic trim stands out for its combination of affordability, durability, and design flexibility. Its ability to withstand wear and tear while maintaining a professional appearance makes it the go-to choice for various industries.

Conclusion

PVC co-extruded plastic trim offers unmatched benefits for edge protection and other applications. Its affordability, durability, and versatility make it a smart investment for any project. Whether you’re working on a home renovation, a commercial building, or industrial equipment, PVC co-extruded plastic trim delivers lasting value.

For more information about selecting the right PVC trim for your needs, consult industry experts or trusted suppliers specializing in PVC co-extruded plastic trim.